- Value:

- £16m

- Sector:

- Tunnelling

- Client:

- Crossrail

- Main Contractor:

- Costain Skanska

- Location:

- London

- Duration:

- 110 weeks

- Given the contract was 9 months late due to poor ground conditions, we worked tirelessly to expedite our works,

- The largest single sub-contract ever performed for Costain/Skanska as a lump sum,

- All works delivered fulfilled Crossrail's performance criteria.

Contact usTo hear about our experiences and how we can help you.

Project Overview

Our tunnelling expertise was called upon to provide ventilation and emergency access to the main running tunnels at two separate London Underground locations – Eleanor Street and Mile End.

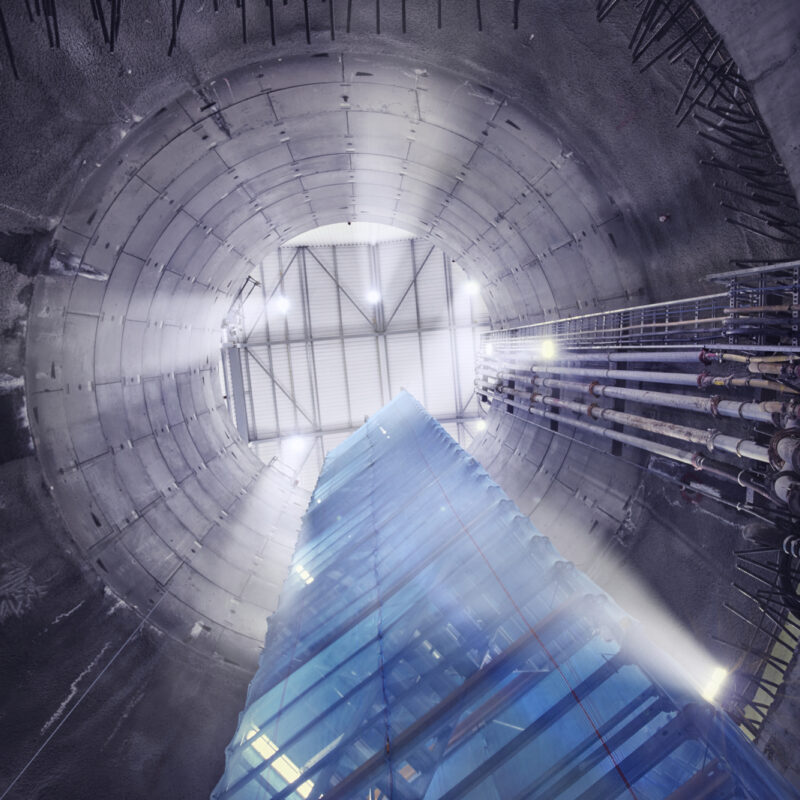

A 16.4m i.d. permanent and 10.5m i.d temporarily shaft were required at Bow Station and a 10.0m shaft at Mile End all of which were 30m deep, located between the two main running tunnels.

Challenges

With notification of access delays of over a year plus delays to the main running tunnel TBMs of 6 months, we were requested to consider alternative solutions.

The proposal for a new temporary shaft saved the client over 18 months by the time the full site was actually available by moving the existing incumbents. We agreed to perform the original works from the smaller shaft through only one access point not four as planned for the larger shaft at no additional cost.

Further to this, it allowed the running tunnel stage one concrete to be installed ahead of schedule. In partnership we were able to collaborate on a temporary works propping scheme for the 8 cross passages to perform all of the connections of cross passages from the rear of the running tunnel.

Both solutions provided critical time savings for Crossrail.

The shaft secondary lining of 16.4m diameter 32m deep with 4 tunnel openings was originally planned as a day shift activity where all 4 tunnel openings could be worked on simultaneously using a full circle shutter. In order to work multiple tasks of tunnelling and tunnel linings only 1 tunnel opening could be concreted at any one time with one steel fixing, one tunnelling and the final one shutter used for tunnel secondary lining.

Added Value Contributions from JGL

We re-tasked the steel lining shutter to pour the lower section of the shaft in 9m high quadrants allowing all the workshops to continue. The shutter was re-designed as a quadrant 9m high with only 20 tie rods penetrating the sheet membrane through special tie sealing units. The lower 9m section was completed in 8 weeks total.

The quadrant was broken up on site and completed as a 3.3m high full circle shutter, during these works 8 hydraulically linked strand jacks were installed over shaft using the temporary works detail utilised during the shaft construction.

A weekend section 61 dispensation was requested from the Council and the full circle installed over just one weekend. Thereafter the remaining 7 lifts of the shutter were achieved in 2 weeks and 2 days without having to remove any sections of the shutter from the shaft, and no work in the lower tunnels stopped or hindered as there were three protected decking levels installed on the shutter, increasing safety and handling.

To hear about our experiences and how we can help you.

Explore related content